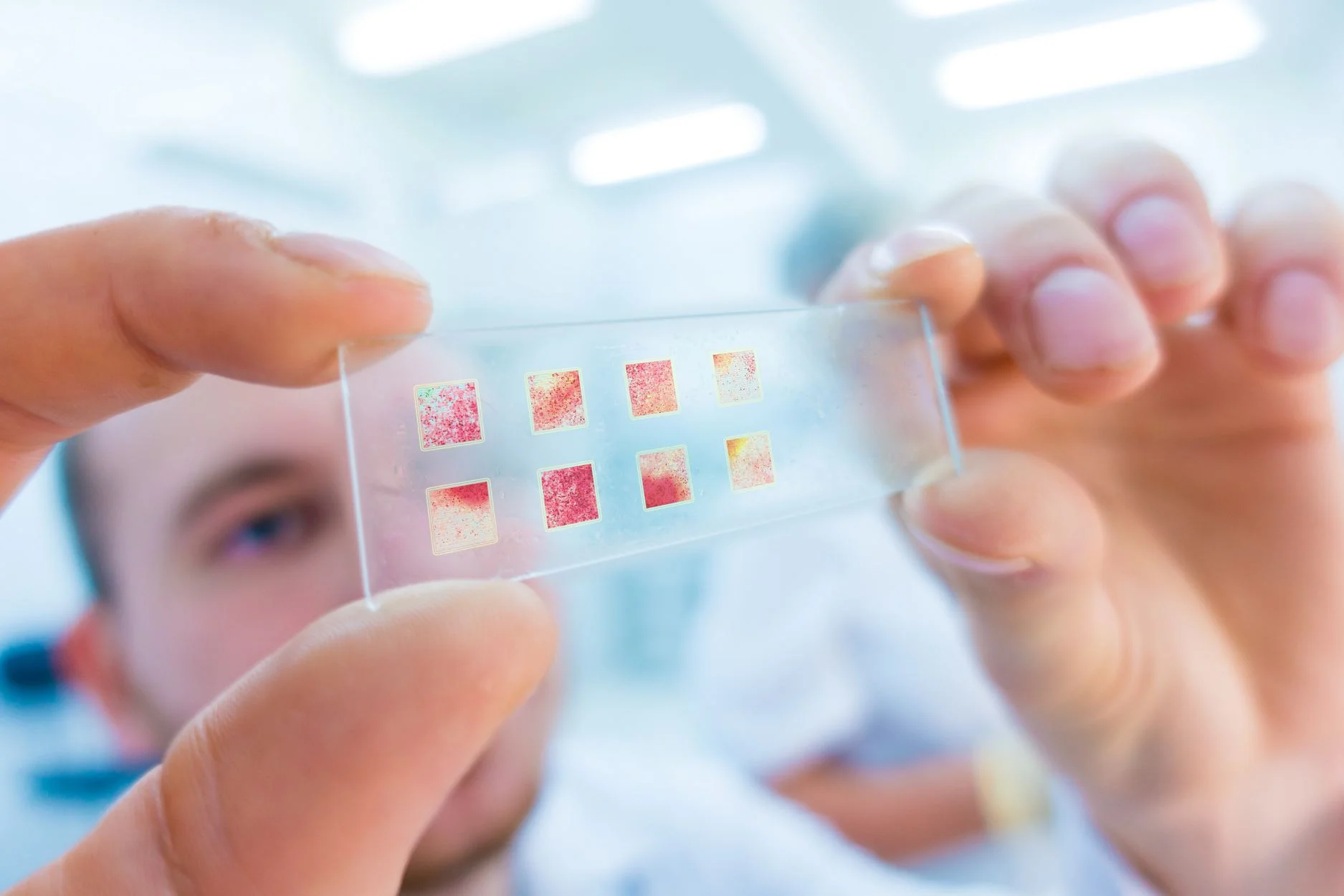

Dip Coating Systems are very useful instruments for Fabricating & Characterizing Self-assembled Structures & Multi-layered Thin Films.

Apex offers Dip Coating Systems for Sol-gel Coatings, Mono-layer Self-assembly & Layer by Layer Assemblies with Controlled Immersion & Withdrawal of Substrates into Solutions. Apex Dip Coating Systems also allow for the easy Formation of Multi-layer Thin Films.

APEX Dip Coating Systems Overview

APEX Dip Coating Systems are built based on the specialised mechanism of it's predecessor the well known SDC series. The onboard micro controller makes it possible to precisely control the dipping parameters that makes even smoother coating. This series also has the ability to display real-time program status on its LCD display in standalone mode and has practically unlimited program memory when controlled by the Computer Software.

NXTdip-150S

NXTdip-150S uses sol-gel method by dipping a substrate into a well of the coating material under controlled parameters to create a thin film of the coating material on the substrate. This versatile instrument allows user to upgrade with many of the advanced add-on features anytime to get the maximum advantage of Dip Coating resulting in better research.

NXTdip-150M9

NXTdip-150M9 uses sol-gel method by dipping a substrate into a well of the coating material under controlled parameters to create a thin film of the coating material on the substrate. The sophisticated mechanism and precise controlling by the onboard microcroller ensures acurate results everytime.

Xdip-SV1

Xdip-SV1 uses sol-gel method by dipping a substrate into a well of the coating material under controlled parameters to create a thin film of the coating material on the substrate. The sophisticated mechanism and precise controlling by the onboard microcroller ensures accurate results everytime.

Xdip-SV2

Xdip-SV2 uses advance PC software and robust hardware and mechanisms for dipping bigger substrates creating an uniform coating upto 250 mm. The substrates are precisely dipped into a well of the coating material under controlled parameters to create a thin film of the coating material on the substrate. The sophisticated mechanism and precise controlling by the state of the art PC software ensures acurate results everytime.

Xdip-MV1

Xdip-MV1 combines programmable robotic arm movement and slo-gel method by dipping a substrate into multiple wells of the coating materials under controlled parameters to create alternate layer of thin film of the coating materials on the substrate surface. The sophisticated mechanism and precise controlling by the onboard microcroller ensures acurate results everytime.

Related Instruments

How it works Learn more about the Dip Coating technology in the Technology Info tab

Send Enquiry

Please fill up the form to help us serve you better

Need Help?

Need Help?